Die Cutting

Our Die Cutting Equipment is Ideal For All Die Cutting Needs!

Die cutting is a featured service of Classic Laminations in both internal production of our easels and the large die cutting volume we do for our customers throughout Cleveland, OH.

We are happy to use your existing die and can assist you in getting a new or custom die manufactured to meet your needs. For storage safety and to expedite repeat die cutting orders we will store your dies free of charge.

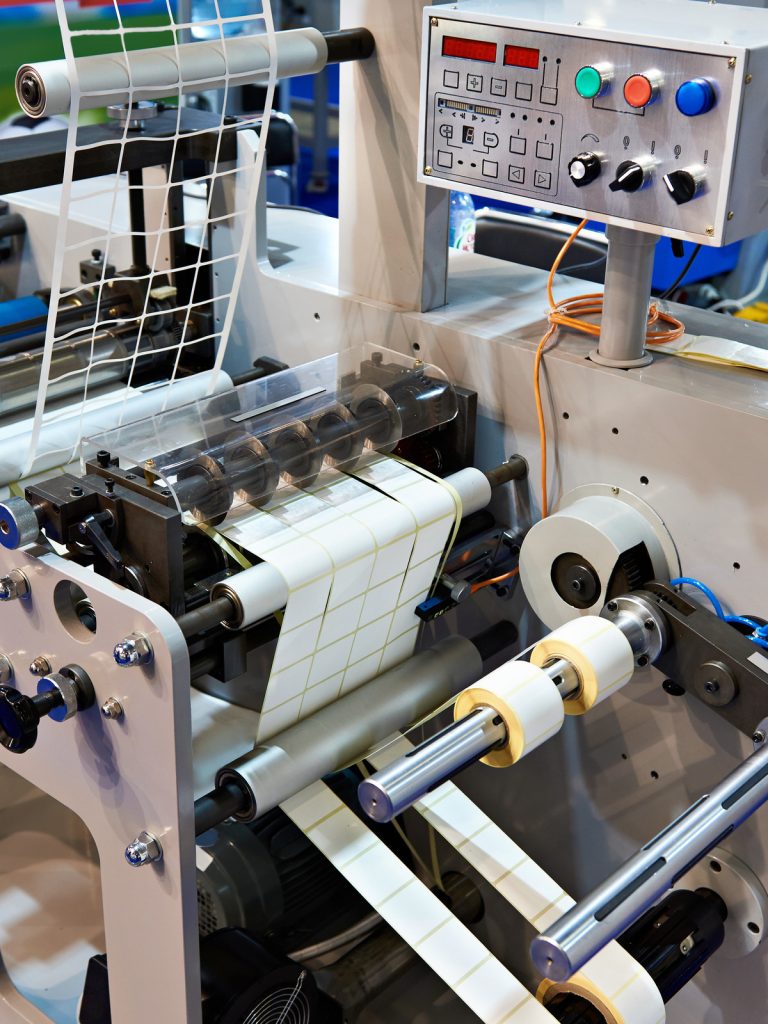

We have seven flatbed and one cylinder custom die cutting machines, including a Heidelberg 22” x 32” cylinder press, a BOBST 30” x 42” die cutter with stripping unit, a Kluge 14” x 22” Diecutter/Foil Stamp/Embosser, two Heidelberg Windmills and two 28” x 40” Thompson Clamshells, and our new “beast”, the Kingsun ML2000 Die Cutter, that can die cut sheets up to 54” x 78”. These help us quickly turn around your custom presentation folders, door hangers, and kiss-cut stickers and label jobs.

Classic Laminations can die cut any weight and type of stock from offset paper to Tyvek and from 3/16″ Fome-Cor® to 40 PT Board. Our equipment and die cutting professionals can handle any size job up to and including 54″ x 78″. With the new Kingsun ML2000 Die Cutter we can die cut a wide range of materials, such as cardboard, corrugated board, plastic sheets and leather. The Kluge enables us to foil stamp and/or emboss letter head, business cards, converted boxes, and POP displays.

We die cut and inventory our own easels. These are available in a variety of sizes in either single wing or double wing style. They come plain, or complete with two-sided tape, to make your mounting projects as easy as possible.

We will protect your die and store it on-site at no charge to you. This allows it to be ready to complete your next order.

We have a wide array of easel sizes in both single and double wing styles for you to choose from. Most are in stock for quick delivery. We can also do custom sizes up to five feet tall.

Don’t just use a cookie cutter off-the-rack vellum bristol door hanger. Let Classic Laminations in Cleveland, OH create a custom door hanger with our die cutting machines. You can coordinate stocks with your corporate print collateral, or use a unique color or finish that will get noticed and give you a better response rate.

We have the capability of transforming your mounted piece into a promotional magnet. We will take your image and laminate it, mount it to special magnet tape, and die strike it to your shape and size.

We have a variety of custom presentation pocket folder dies. We use these to make pocket folders with a dynamic, memorable impact for corporate meetings, tradeshows, and more. You can also bring in your custom die to create a pocket folder specifically designed for your needs. We will die cut, glue, and if needed, laminate the piece(s) to give you beautiful finished pocket folders.

Send us your printed image, and we will laminate it, mount it to a special nonskid pad, and die cut to shape and size to create a durable counter mat used for retail sales applications. These eye-catching counter mats will help drive sales by providing quick and convenient access to product information. We can also produce custom mouse pads which are a great selling tool.

We can custom kiss-cut your PSA product. Just ask us how to get a custom die designed for your particular material. This type of die cutting cuts through the facestock and pressure sensitive adhesive, down to, but not through, the release liner.

These are the sharp, steel rule that cuts a variety of paper and substrates. This rule is usually hardened, whereas a softer rule is needed for curves.

This is the process that is also known as die striking. It is a print finishing operation that uses sharp steel rules or knives to cut a specific shape into a substrate. It can also cut the substrate itself into a specific shape that cannot be accomplished by a straight cut on a web press or a guillotine cutter. Common projects that use die cutting include creating pop-up books and games, door hangers, stickers, labels, and to cut flat printed sheets into various shapes.

This process is often done on either flatbed or rotary presses. Rotary die cutting can be done in line with web printing. Die cutting can also be done with circular dies, thermal and clicker dies, as well as machined compound and progressive die tooling.

This is the machine that holds the die and cuts the material into specific shapes.

Term refers to the area to be die cut.

In rotary die cutting, the rotating shaft that holds the die.

Reference term for the hardwood plywood that is used as the carrier for the steel rule in cutting dies.

This is the process of forming or manufacturing a cutting die.

Reference term for the die cutting process so named because the die strike depth is precisely controlled to cut through the facestock and adhesive layer of a pressure sensitive adhesive laminate but does not cut into the release liner. The die “kisses” the release liner resulting in pressure sensitive labels or stickers that are easily peeled from the release liner. It is important to cut deep enough to completely cut the facestock and adhesive but not so deep as to cut into the supporting release liner.

This is the hand tool used to remove steel rule from a cutting die.

This is a rule with a rounded edge designed for creasing or scoring paper or board.

Term referring to a rule with teeth or sharp projections designed to make perforated cuts in paper.